ギシナビNews【第4号】

2020/09/07

Evaluation of 3D foot morphology custom insoles in safety shoes: plantar pressure distribution analysis

Akouetevi Aduayom-Ahego, PhD

【Introduction】

To prevent injuries in working places, employees have to wear safety shoes for more than 8 hours a day. Long working hours in an industrial environment with safety shoes can increase the development of musculoskeletal complaints. In a previous study on occupational footwear, Johnson1

stated that prolonged standing and walking on hard floors might be the main causes of foot problems while wearing safety shoes, shoes that do not fit correctly, and a habitual wearing of the wrong shoes. These safety shoes when not well stabled can cause fatigue and falling during working. To reduce and prevent the risk of falling in working environments, the stability of the safety shoes needs to be considered. The aim of this study was to evaluate the effects of safety shoes on gait and plantar pressure distributions on an industrial flooring with newly customized insoles (Dream GP Inc. Japan).

【Methods】

Seventy-two workers (52 males and 20 females, age: 48.2 ± 10.5 years, height: 165 ± 3.9 cm, weight: 66.9 ± 11.5 kg) participated in the study. Custom insoles were manufactured based on the 3D morphology of each participant foot. The old shoe and new shoe with customized insoles gait data were collected using Footscan pressure plate (Rsscan, Belgium) in 6 months period for evaluation. A paired t-test was performed to compare the maximum pressure of the old and new shoes during 6 months period of 3 anatomical foot regions (Forefoot, Midfoot, Rearfoot).

【Results】

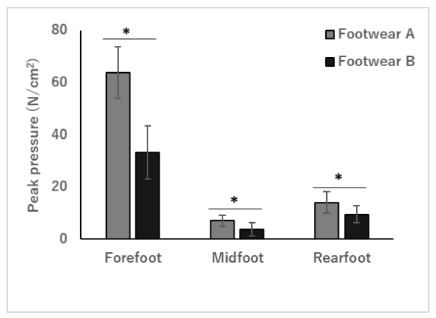

The maximum plantar pressure evaluated in the different zones showed significant value during the 6 months period of wearing the new shoe and insoles. From heel to toe, the old shoe showed higher pressures and force. The new shoes fitted with 3 D foot morphology customized insoles reduce considerably the maxi- mum plantar pressure (Figure 1).

The maximum plantar pressure evaluated in the different zones showed significant value during the 6 months period of wearing the new shoe and insoles. From heel to toe, the old shoe showed higher pressures and force. The new shoes fitted with 3 D foot morphology customized insoles reduce considerably the maxi- mum plantar pressure (Figure 1).

Figure 1: Comparison of peak pressure of the foot regions be- tween the two footwears,

*p < 0.001

【Conclusion】

Our study analyzed the foot in 3 regions anatomically: forefoot (phalanges and metatarsals), midfoot and rearfoot. The Dream GP insoles evaluated in this industrial environment have a great influence on the plantar pressure distribution. It can be inferred that the reduction in pressure observed in the new shoe and 3D customised insoles conditions compared to old shoes condition resulted from the clearly distributed over a larger surface. Also the effects of the insoles in the new shoes have tendency to stabilize the body laterally during propulsion phase of the gait. Using a 3D foot morphology customized insole will improve gait comfort and stability thus preventing fatigue, injuries and falling in an industrial environment. The results may have guidance for the design of 3D insoles and footwear for industrial workers.

【References】

1) Johnson J. Footwear alleviates aches, fatigue through better fit, shock absorption. Occup Health Saf 1994; 63: 68-69.

2022/01/11

ギシナビNews【第20号】2021/12/28

ギシナビNews【第19号】2021/11/19

ギシナビNews【第18号】2021/10/05

ギシナビ News【第17号】2021/09/06

ギシナビNews【第16号】2021/08/05

ギシナビNews【第15号】2021/07/06

ギシナビNews【第14号】2021/06/14

ギシナビNews【第13号】2021/05/07

ギシナビNews【第12号】2021/04/06

ギシナビNews【第11号】2021/03/05

ギシナビNews【第10号】2021/02/05

ギシナビNews【第9号】2021/01/05

ギシナビNews【第8号】2020/12/08

ギシナビNews【第7号】2020/11/05

ギシナビNews【第6号】2020/10/05

ギシナビNews【第5号】2020/09/07

ギシナビNews【第4号】2020/08/05

ギシナビNews【第3号】2020/07/06

ギシナビNews【第2号】2020/06/10

ギシナビNews【創刊号】